[quote/]thanks, don’t know what went wrong with the post above anyway did the new seals solve the problem ? and what method did you use to fit them/ push the barrel in did you use any lube eg rubber grease etc .

I’m a bit puzzled to how the seals ended up split its only a month old was it done during assembly maybe[/quote]

As my original problem was blowing from the between the top of the breech seal and the probe I suspected that this was caused by the breech seal holder being too high in relation to the probe so I replaced both probe and breech seal holder.

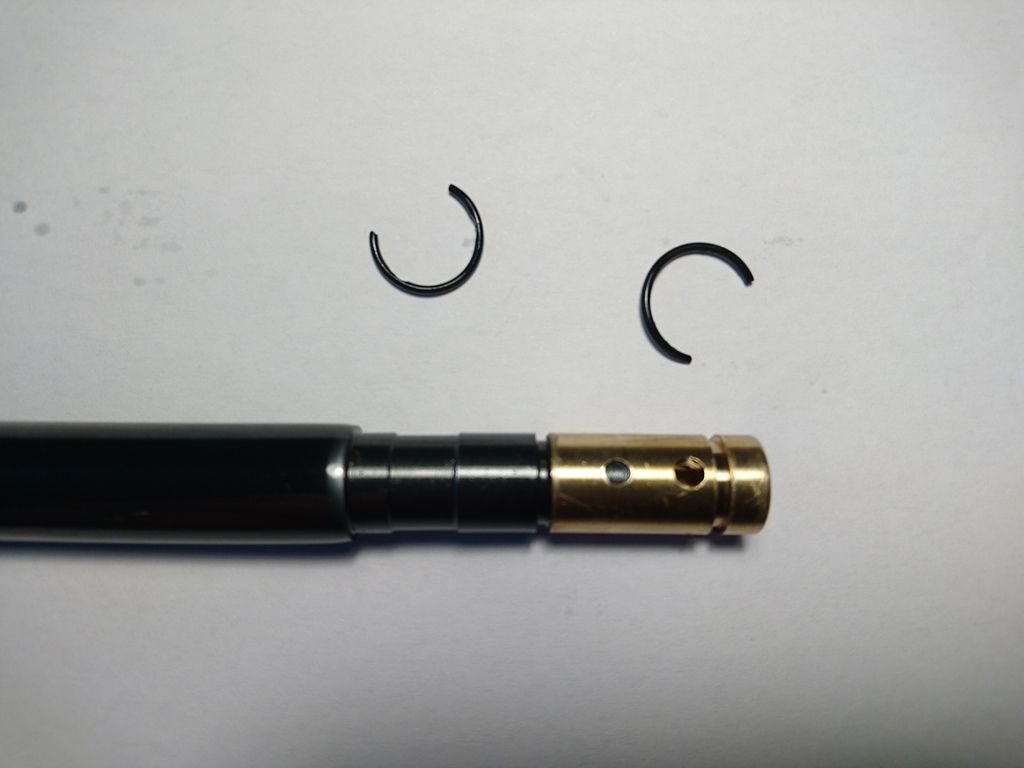

The S650A seals fit in the groove on the outside of the breech seal holder and (I presume) on the barrel in the groove formed between the barrel and the end of the seal holder. I was only aware of the one which was fitted in the groove on the outside of the breech seal holder itself - so only replaced that one. Julian said to use plenty of silicone grease to ease fitment. After removing the old breech seal holder I coated the portion of the barrel which fitted into the holder with loctite, inserted the barrel into the holder (ensuring that it was in its original orientation) and wiped away any excess. I also tightened the top barrel grub screws very lightly following Julian's advice. However replacing the breech seal holder and the S650A seal didn't work as I ended up with very bad leaks not just from between the top of the breech seal and the probe (my original problem) but also rearwards from around the breech seal housing and also forwards where the barrel itself enters the bolt housing. It was obvious that air was leaking into the bolt housing from either the holes in the breech seal holder or the joint between the holder and the barrel.

So I removed the barrel to find that the new seal had actually split. I binned it and ended up "simply" wrapping a few layers of PTFE tape around the breech seal holder and the barrel almost to where it exits the bolt housing before coating in silicone grease and refitting. Then with the barrel refitted into the bolt housing (it was now a very tight push fit) I used a cocktail stick to delicately remove any PTFE tape from the transfer port hole and then to apply loctite into the transfer port hole in the bolt housing in the hope that it would seal any gap between the transfer port hole in the bolt housing and that in the breech seal holder. I took care not to get any past the transfer port hole in the breech seal holder and therefore into the breech itself. I had already added loctite to the hole in the breech seal holder adjacent to the transfer port hole prior to refitting the barrel assembly into the bolt housing.

As simply replacing probe, seal holder and the S650A o ring hadn't stopped the breech seal/probe leak, and despite Julian's advice not to (as overtightening the one nearest the breech could actually deform the brass breach seal holder) - with heart in mouth I tightened down both top barrel grub screws (sorry Julian) to push the barrel and breech seal holder as far down as possible. Though I now knew it was a risky thing to do I figured that if it did deform I'd just get another breech seal holder from Julian

The result of all this? NO LEAKS AT ALL

- I still can't quite believe it.

And fingers crossed that it stays that way - I only did it yesterday - if not I've got a pretty good idea of what I need to do again

(I've only had my 2013 S400F for a few weeks and it's been blowing from the breech seal since I got it. I'd already replaced the breech seal a few times without success and if this attempt to sort it didn't work I was going to get shut. The experience of this, my first venture towards the "dark side", caused me to lose faith in AAs so I was looking at px'ing it for an 177 HW110. I'd have done so by now but BAR are out of stock of them at the moment. However I don't like to be beaten so persevered with the S400 - luckily)